@marcdraco Okay so I have skimmed through this whole 35 pages thread. The only thing I have ordered thus far is a 25mm condenser capsule.

I am looking at your GitHub and wondering which version of the preamp you would suggest going with. I see the latest V2 being the Katie songbird. Is the V2 pro coming out soon so I should wait or do you have any other suggestion?

Also do the schematics include all the neccessary components?

Only show the spoiler if you want a peek behind the curtains and are prepared to risk making a V1.00 design.

Pretty much everything on GitHub has already passed QC. The 48V module looks to need a little work but I haven't actually used it "in anger" so to speak.

<SPOILERS>

I can't say when (or even if) Matt will do a video, I have no control over that side of things, but if you have the constructional ability, Nightingale is more compatible with the original design (and can use the original capsule with the lovely brass fittings). The THAT has been replaced with a low-noise discrete design and the NMA0515 is no more... A new "head" is under development but that's a few weeks off at this stage.

Linnet is stripped to the bare bones although can does use a "nicer" capsule like the ones you have there, there's an option to fit a really low-cost capsule such as the Panasonic WM61a (discontinued but NOS is still around) or alternatives like the PUI Audio POM-3535L-2-R. These capsules contain their own JFETs and don't require a complex screen.

Linnet (being the lower-cost option) only has micro USB-B whereas Nightingale additionally has USB-C.

Technically both boards (I'm literally finishing the Linnet routing right now) have the facility for a single-ended capsule, including running the original brass-capsule design but the differential version does appear reduce distortion a bit (though unlikely it'll be audible).

Linnet will be on GitHub soon, Nightingale is actually completed (for my own prototyping) but it won't be on GitHub for now. Have to keep some things under the hood. 🙂

Both boards appear to be in good shape but I advise everyone to hold off until I've had at least one made up - just in case! If you want to get ahead of the game and you have the skills to check the schematic, I'll send you the KiCad 9 archive but I'll warn you that, being a development version, it may have minor or even major faults.

<SPOILERS>

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco Thanks for the quick reply. I plan to make my own stand and head and so forth so my only real concern is the electronics. Sadly I am not versed in circuit design so even if I got the kiCad project it would not clear up anything. If you plan to release Nightingale in the future I am happy to wait since I don't really have much time during June anyway and would not progress with the project.

If you do not plan on making it public yet I might just go with the Bobbi starfire unless you would suggest a different one which maybe focuses on audio quality even if it needs a separate power supply.

We're kinda spoiled for choice at the moment. I'll have to pare it down somewhat so the production versions are clearer.

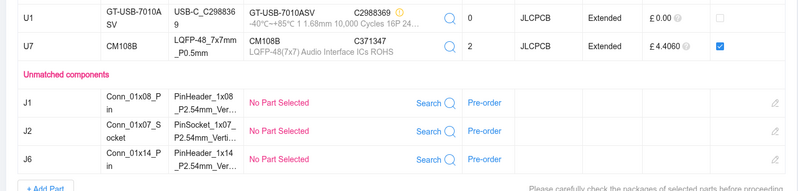

The gotcha with buying from China (i.e. JLCPCB in this case) is they charge extra for "special" components such as USB connectors, pinheaders and even electrolytic capacitors. These are the sorts of parts that can be sourced locally on eBay (or in your spares box if you have a collection). Hence it's a case of only factory fitting the stuff that's absolutely got to be SMD and limiting what JLC call "extended" components to a minimum.

The full board is almost entirely SMD with THT jumpers on a 2.54mm (100 mils) pitch standing in where we need to take a tap for something so it can be fitted in a case.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco Oh yeah I have no issues waiting 4-6 weeks. Will probably just go with the full version of nightingale once you release it.

I have used JLCPCB before and I only ordered blank pcbs thus far. I even soldered some SMD stuff by hand just because it came out cheaper (it was just a couple components I would not bother with a whole smd board). Do you perhaps have an idea of the aproximate cost that JLCPCB would charghe for the full version with SMD components?

Looks around $16 per board with DHL shipping plus taxes. I haven't suggested this to Matt, but they will be better crowd-sourced (the more we order the cheaper everything gets). You don't need to add much in the way of parts - you can even get away with a fixed gain resistor (which you get by trial until I've had a chance to calibrate a couple of different capsules). I hope we can get an eBay seller to carry them - as neither Matt nor I are geared up for stock management. You could always get two (the extra boards are pennies) and sell one for a profit people who don't want to wait. Most of the cost is taken with the crystal and the TI chip. Almost everything else (save the output caps) are fairly everyday items. Some of the SMD parts are pretty small though as I've had to use a fair number of 0402 parts and they're tightly packed.

So apart from the capsule and a headphone socket, they're pretty much ready to go. The cost managed one will be around 1/2 to 2/3 of that.

The others aren't deprecated, they fill a different niche, primarily for people who want to do a lower-cost upgrade, esp. Regan which is entirely through-hole.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco Oh cool to see that. I will be keeping my eye on this thread closely then.

@marcdraco also I have seen your message but cannot reply since I need 5 approved posts on the forum. Think this one might be the 5th.

You can reply now, you're out of the moderation queue. It's to stop spammers - and trust me, we get a fair number trying it on.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

Im looking at recreating the V1 from the original video mostly due to the excellent instructions in the form of the video itself. Would I be missing out on much compared to attempting V2(or the in progress "pro" version)?

Yes and no. (Talk about hedging my bets...)

The published ones at GitHub (and there are plenty to choose from) do require further instructions but were mostly a bridge between what I'd promised Matt and the real V2 which is just being tuned in KiCAD now. The new one is a true successor with pretty much every useful metric tuned. Version like Michelle were developed for people who are unable to access chips such as the THAT1512 which can be hard to locate (if you want a genuine one that is). I've kept the real one very much under wraps because it's a complete, ground up re-design with all the best features of the original but broadly at lower cost overall for the basic setup with options for expansion. The first prototype has a few bits I need for testing but as soon as I've validated it all works correctly, I'll publish it to GitHub and everyone can have crack at it. It's been in development for months with a couple of hold ups like one of the parts going into short supply and the heatwave making it difficult for me to think, let alone solder! 🙂

You'll have noticed that I move at a glacial rate but that's largely due to my tendency for perfection (within reason) for a four layer PCB, it's easier with six or more but that gets rather expensive.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco Does the new design still use the original capsule(JLI-2555BXZ3-GP)? Thats the only thing I actually ordered so far so I wouldnt mind waiting if I will be able to make use of that part still.

Yeah, it's 100% compatible with the original head (even for those who have built and encapsulated it in brass). This was one change I've refused to make for the V2 but the rest of the signal chain has had a complete re-design from the ground up. It's not that there's anything wrong with the original per se, but I using an SMD PCB gives me access to parts that just aren't made on a 100mil (2.54mm) pitch.

You have a wider selection of JFETs for reasons not really worth discussing but the original JFET is an excellent part. Even the gain switch retains the same basic resistor set although sensitivity is predicted to be better. The JLI2555 is a perhaps the best GP "FETLess" back elecret capsule currently in production. To get better you have to go to a polarised capsule but those tend to run costly. I have a working example here but it's not ready for prime-time as yet.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

I decided to write a post about the final result of V1 in Matt's design.

I should clarify that I am using the SSM2019 preamplifier while waiting for the THAT1512 to be delivered from the US. It has a very similar tadashite, and the result will surprise those who are not yet familiar with it.

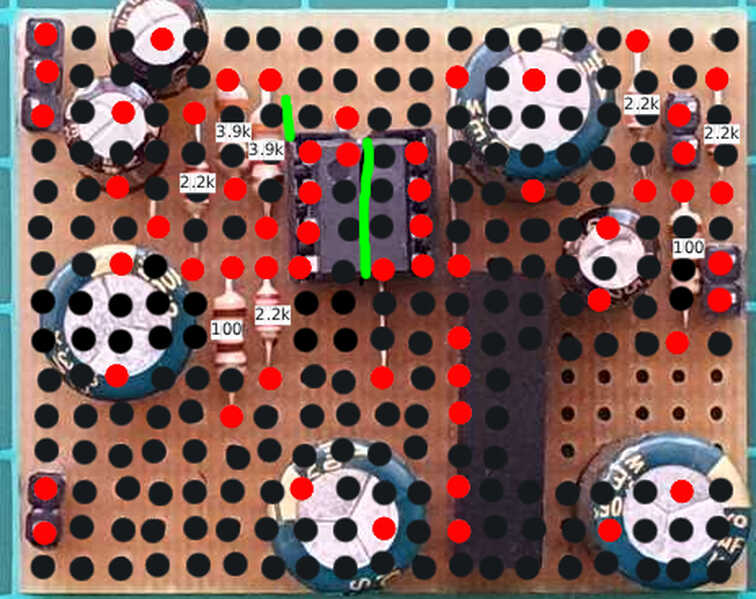

At first, I tried using a perforated board, but even after assembly, there was still a little noise that wouldn't go away, even after changing many variables. In the end, I came to the conclusion that it was the board itself.

For the final version, I decided to use a printed circuit board from Electronoobs.

I used a 0.12 mm shielded wire from the capsule to the amplifier, 3 mm wide.

There were many different wire options because they had to pass through a brass tube. Many of the options caused noise, but with this wire option, I was able to eliminate it.

Below is an example of the sound quality without any processing, as well as a photo of the microphone itself.

Vero is not ideal when you have a HF floating around the place, the noise from the NMA0515 is the worst source but a fair bit can creep up from your laptop, seems less of a problem with desktops, but it can still happen. A properly designed PCB should always give better results because we can control the fields more accurately.

Very nice work there.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco thats great to hear! Ill be eagerly awaiting your new design. Thanks for the time and effort you have put into this!

Yup. @polaryeti is dead right. Even V1 is quite superb. It's a LOT easier to look at someone else's design and take inspiration from it (which is what I've done), analyse for mistakes (again, WAY simpler when someone else has done the grunt work) and fix them. I've pushed my own skills beyond my limits and walked into territory (>1GHz on the rails) that I've always avoided.

But wait, 1GHz - that's well outside the audio range, right? It is but when you've got a high-speed mixed mode design (and these will give you some clues about the real V2) the clock edges are switching from 0 to 3v3 and back again in times measured down in the nano-seconds or less. As Rick Hartley puts it - even if your board only switches once ever 24 hours, the actual edge is so sharp that it produces harmonics to moon! And that means (if you mess up) the board is infected with fast moving edges and your nice, high-impedance audio signals sound like there's a thunderstorm.

V1, despite being made on experimenter's board (stripbboard, often called Veroboard in much the same way we call Hook and Loop material, Velcro) is brilliant.

And that's why development of V2 - as a true successor to the king of Maker mics has had such a long development phase.

Phase one was to make a board with the same functions as V1 but with better noise suppression to get that noise floor down while putting less load on the USB supply. Over time I experimented with P48 (professional) phantom power but came to the conclusion that more electronics causes more noise. Not much but enough to give me pause. A P48 one is sat in "the lab" complete with a 5 to 48V boost converter and that might appear eventually, but it's only really useful for unbiased capsules which cost >$150 a piece and frankly the TSI/JLI-2555 is more than sufficient for a vocal mic. It's a little peaky in the higher registers but most people find that more pleasant than the flat response. Larger capsules (because of physics) tend to be more "boomy" and the 25mm size is a nice compromise between 10mm (about the smallest you can get with a cardioid response without resorting to MEMS units and the 34mm standard used in the "pro" capsules.

I can do a MEMs "head" if there is call for one but they require a more expensive production board due to the "breather" hole which has to be drilled underneath the mic - which itself it only a couple of milimeters square. These things are incredible with an ASIC chip on board to make more responsive to applications like very high-end headsets like this one: https://invensense.tdk.com/download-pdf/ics-40800-datasheet/

It's very easy to lay out the board and they typically only require a couple of volts to drive them, much like a classic electret, although C0G capacitors are a MUST if anyone wants to take a crack at it. V2 has an extra input (assuming it makes the final cut, which it might not) to accept another mic.

For headset use you can use a small fixed board for the mouthpiece (perhaps made on a 3D printer) and either a flexy PCB or some jumpers to wire it to the remote electronics - which, naturally, go into the earpieces. I've done all the boards necessary for this but they aren't all in one at this stage. If there's any call for one, I'll do that after the V2 is complete as most of the schematics are ready, they just need laying out. I'll leave that one up to the community and Matt to decide.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

Hey all,

So I finally got my first batch of Michelle starfire PCBs back to try and make this project and I had a couple questions/am seeking some advice. Some can be answered more generally and some might be for the man (the myth, the legend) himself marcdraco.

1. the 220 radial inductor is marked as optional. I don't even pretend to have a complete understanding of how the PCB works or what this inductor is doing, so is this a "not needed but it can only help so why not" or is this a "if you have x+y+z then you want it and if you have m+n+o you do NOT want it" situation. and if it's the latter ... when do I want it.

2. is the text on the bottom "* For compatibility with the "FET only" head from V1 series. 680R for advanced users for P12!" a single statement or two statements and if it's 2 statements what is the * referring to (I wondered if it was referencing the inductor from before)?

3. the 680R through hole resistors are for the P12 as the text suggests. I have the JLI-2555BXZ3 because it seemed good and was less expensive to accidentally ruin in the process of learning. Given that this is not P12, I assume I actively DO NOT want those resistors, in which case should I just leave them open or bridge the holes? (at least, as far as I can understand the JLI-2555 is not a P12, though maybe it is ... honestly looking this stuff up can be crazy confusing due to lots of things primarily using colloquial legacy names that everyone still uses, and that's saying something coming from someone who does genetic engineering for a living where every protein has like 10 different names)

4. In the original video he uses a rotary switch with a bunch of resistors. This seemed super complicated to me but I assumed at the time it was due to wanting a log scale (or at least close) and anything out there would be linear. But some browsing on digikeys and similar show a fair few rotary potentiometers which max out at 500 ohms that are log scale which are close in price to a rotary switch alone. So is there any good reason not to use these as they seem easier and way less prone to failure than the complex ring of resistors in the video.

4b. if a log potentiometer is totally fine, is 500 ohms still a good top resistance for the gain on these new boards (specifically the Michelle Starfire). Would it be better to get one that goes up higher than that (it seems like 1000 ohms is pretty common and available) or does that give too much rotational space to gain values that you would never possibly need.

5. In the years since the original video has anyone come across a better basic audio interface that's usbc from the get go? or is the best course of action still the basic usb and then breakout board?

Thanks to anyone with thoughts on any or all of these questions.

@marcdraco I truly love this project and its honestly been the perfect combination of handholding and figure it out for my recovering, post meltdown, newly diagnosed ADHD brain. Given the naming of your Jane board, I thought it worth telling you that this little passion project of yours has made a meaningful difference beyond just "a good mic" to at least one person. Your excitement for this stuff and palpable, keep up the amazing work!

1. The inductors were experimental as part of a high-frequency filter to crush some of the worst of the 90KHz ripple produced by the NMA0515 and recommended by Murata itself. They form a low-pass LC filter with a cutoff around 3KHz but for all practical purposes the capacitor multiplier does a far better job of it.

2. The resistors for P12 and the original design are different because P12 (P24 and P48 standards) demands TWO +12V DC rails which was more convenient I expect when we were still transitioning from valves and the DC bias was sent via the centre tap of a transformer at one end and recovered by another at the mic. This gives a nice common-mode DC which is easy to remove and requires less cabling.

Fast forward to now and only the old guard like me still use transformers (I only use them for very specific purposes like impedance matching in the ribbon design which might make it to Perks in the next year or two, so don't hold your breath. 😏). I think Matt must have based his design on the guts of a commercial model which had access to split supplies and that meant we don't have to faff around with the restrictions P12/24 and 48 bring - mostly very limited current. A typical P48 mic can only draw about 4-5 mA before the supplies buckle to the point where there's no useful power to drive the transistors.

As regards jiggering the capsule, that's pretty much impossible as they are capacitors (albeit pre-charged) so DC has little to no effect on them. I've proved this experimentally but no one states what the breakdown voltage is for their caps since you're not really supposed to put DC on them. It's far easier to accidentally knock the ground tabs clean off the JLI capsule while the clones use thicker (and likely cheaper) alloys.

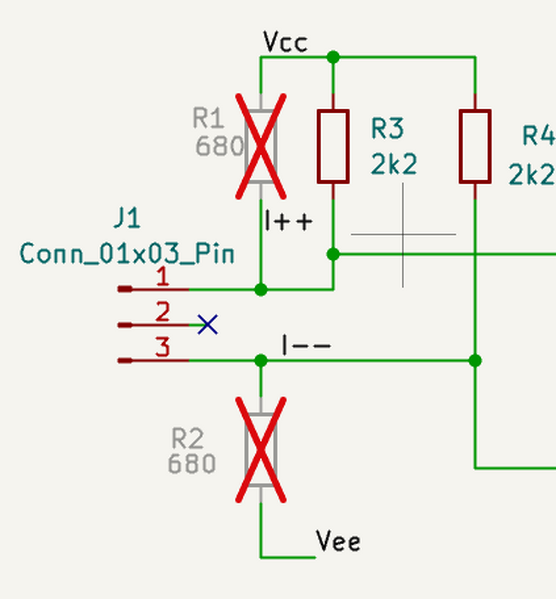

3. There's an error on the silkscreen (this is what happens when I'm staring at a board for days on end and I make a change that I forgot to reflect on the silks. (There's another one for the detailed paper coming out later.) If you power up your board you should see roughly 12-14 volts at the outputs with the two 2K2 resistors in place. I've been a bit short of beta-tested of late which is how silly errors like that creep in.)

In fact, the 2K2 and 680R resistors are back to front on the schematic as you can see here. There are two ways to set this up.

12V DC on each rail (as shown here with the 2x 2k2 resistors) OR remove those and put the 680R in place to have a split rail - call it 12V and -12V although the exact value doesn't matter all that much.

Probably would explain why a chap I did send one over to couldn't make his work! I'll have to drop him a line and explain. I couldn't figure out what was wrong until just now (it's many months since I did this one and I've been flat out on the new Songbird series which are a complete re-design from the ground up. Starfire were the last ones based on the Murata boost converter. The new ones have a much more powerful and yet far more compact IC from TI to do the same job but it does it at >2 MHz so it's far easier to filter.)

Anyway, to navigate that mistake, you'l just need to remove R3 and R4 and put 2k2s (not 680Rs!) in the through hole points. This should bring everything into line with Matt's original but with Doug Self's alternative preamp. For a circuit that uses the generally considered noisy TL072s it's remarkably quiet.

In keeping with the upgrade from V1 to V2 (there's a V1.5 of sorts in production at JLC now) I've swapped out the THAT1512 for something completely different that allows me to do more in less space. I can't say more in public in case (a) I jinx it and (b) it takes longer to get the prototypes to reach viable build quality, that's to say, no one will have to do SMD surgery to swap parts out! :/

Over the last couple of years (as KiCAD has improved) I've tinkered with new features which saw me drop some absolute clangers including leaving an 0402 resistor off one of the P12 capsule adaptors rendering it pretty useless as that was part of the DC filter. No DC? No output. so rather than Open Sourcing experimental boards during the development I'm keeping it secret(ish) so people don't drop their hard earned on faulty or failed boards. I had tested them here but my stuff was all set up for P12 and the designs are quite forgiving.

The advantage of the methodology Matt used is primarily simplicity - just drive the FET and forget about the rest of the stuff to match the line impedance down to 50 ohms (essential for very long runs) as capacitive effects in the cable start to rear up after a run of a couple of metres. Short runs like this are fine with a simple shielded twisted pair. That stuff is explained in the paper. This is easier to assemble at home on a bare board like Woody and Minima and lower noise because there are simply fewer components in the signal chain.

4. Matt used switched resistors to fix the gain in a more professional standard manner. Infinitely variable gain is all well and good in a home studio where you can (at a pinch) stick some blu-tack on the knob to stop the cat moving it ... (thanks Walter). Yeah... bit of a bind if you're recording something or come back to your setup only to find someone has altered the gain. The other benefit of this method is you can fix the gain in dB (20, 30, 40... etc.) by steps which correlate nicely with how humans perceive the relative loudness of sound. Do you need one? Absolutely not, a 500R rotary is absolutely fine although be careful as you approach the low end (max gain) of the pot as it might go into oscillation.

5. There are a bunch of better USB interfaces out now with sampling rates up to 192KHz some of which are so small the entire thing (it's probably an ASIC chip) fits into a short wire with a USB-C at one end and a 3.5mm TRRS socket at the other. Which is great if you have a headset with a TRRS output but not so much so if you want to hook it up here. Soldering a TRRS plug isn't for the faint of heart, but it's doable with a microscope and fine-tipped iron. Beyond my meagre skills. (My excuse is that I often get "the shakes" as a side effect of some of the crap I have to take to keep me breathing, still better than a cheap wooden box into the furnace, eh?)

I can tell you that as part of the V2 upgrade (which is massive, BTW) I've included a 48KHz ADC with USB-C on board as standard. Now that doesn't sound like much of an upgrade but there's more to it than that as I'll hopefully be able to demonstrate if the new prototype works as expected. It comes with its own mic (an omni, so not as directional as the cardioid you're using) but there's a reason for that which I can't explain as [SPOILERS]. And no one needs that right? Slight spoiler though - this thing isn't your everyday Chinese digitiser...

I'm using the CMedia CMI108B in this design as it's low cost, doesn't require a Xtal oscillator (as the TI base chip and CMI's earlier one did). This is a cost-saving exercise as much as anything but the CMI108 (the "A" version I think) is found in some commercial offerings. The other thing with the TI was it's in short supply and may be moving to redundancy which would throw a huge spanner in the works.

The new analog section has a better limiter design to prevent the ADC from getting blown to bits (which happens on some versions of the original because it can pump out nearly 28V (peak to peak) which is nearly six times what most USB digitisers can cope with. The CMI108BB max input is only 0.3 -> 3.96V. Exceed that for a few microseconds and "poof" no more ADC. Lovely!

The diode limiter I've used previously is quite aggressive (by design) but does limit the maximum output level the ADC sees which means you do have to run the gain at the digital end a bit which, naturally, also boosts the noise floor and we don't want that. It was a choice (at the time) to put a simple limiter in and live with a little more noise vs. blowing up another £20 device. I think Amazon would have spotted a pattern if I kept returning them. 🙂

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

The V2 is past my current ability, anyone skilled enough just want to make one for me? I will pay $100 hahaha

Don't worry too much, I'm revising it (following suggestions from mein host) to make it more modular so pretty much everything plugs together. There's very little soldering (and what there is, is quite straightforward).

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

I will trust you! hahaha

It's mostly headers and most of it mates together so you can mix a match, all things being equal.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

Hello, I'm new around here but after watching the video I really wanted to make my own version. I don't have much electrical background though I am a mechanical engineering student so I might understand some concepts. I have a few questions, though I'm not sure if they have already been answered.

Which components need to be brass, as I would prefer to 3D print my own components?

- For example, can I make the cylinder around the microphone out of plastic (there was mention of it all needing to be grounded)?

Is there a shortest length of O-ring material before the "suspension effects" (sorry I don't know the terminology) don't work?

Do the brass arms add to the "suspension effects" or are they just for articulation and positioning?

Again, apologies if I'm repeating questions. I really appreciate the help 🙂

The capsule absolutely has to be screened. The brass ring, brass gauze, etc. prevent stray noise (and this thing picks up everything in a 1/2 mile radius, OK, maybe not that far, but a long way). If you make it out of plastic, it's going to hum so badly, you won't hear a thing and the overdrive may even damage the parts.

If you want to know a little more, it's a Faraday cage, named for Michael Faraday, and it's were electrical energy gets trapped so nothing on the inside can get out and nothing from the outside can get in. It's more the reasoning and actual physics are technical than that of course, but that's what it does.

Something a lot of us find hard to understand (because we're used to routing electricity through wires) is that the energy - the "fields" - electric and magnetic - travel through space. I blame school physics where this really should be taught but is either poorly explained or just glossed over. Electrical energy is just another form of what we perceive as light, it's just that our eyes happened to react a very narrow band that we forget that there's a huge spectrum of it - flowing throw all of space.

In principal, you could line the inner of a plastic mount with something like slug tape (which is a thin, self-adhesive copper foil that gardeners use to keep slugs from climbing into planters and laying waste to soft tissues like squashes (cucumber, marrow) and lettuces for example. The thickness is less critical than making sure that sufficient of the surface area is covered. You could, potentially, test-bed it with plastic and order a final design in steel from JLCPCB or some other 3D metal printing shop, but that's likely to be expensive.

Beyond that (and the screen around the cable, but you can use braided microphone cable if you prefer) you're free to do adapt it to suit your own tools and materials, even design.

The suspension mounts are there to absorb low-frequency vibrations. They don't have to be very long - it's the elastic modus that matters - specifically the amount of energy the material absorbs before it hits the capsule assembly. Many professional mics (few of which look as good in my opinion) often have soft plugs of a rubberised material that is quite malleable and the effect of that and the weight of the capsule tend to ensure that vibrations don't get through to the super-sensitive moving foil that creates the sound we hear.

Good luck with your build!

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@pygmalion You're awesome man, thank you. If anyone else is taking this approach, here is a template I made to follow his soldering schematic:

(This is in response to this specific post in this monstrous thread: USB-C Microphone (official topic) – Page 5 – Microphones & Mic Preamps – DIY Perks Forum). I added which pin holes are soldered (red dots) that should line up with the holes. Also the resistor values. I will update if my microphone works, I have a bad feeling that the Ali Express THAT 1512 I ordered is also a fake, so I might have to get another one of those, but overall hopes are high!

Also here is another template I made to understand the DIY Perks template without having to print it out (for comparison with pygmalions)

Thanks for the quick and detailed reply! It's looking like this project gets more intense the more I look into it haha. Do you have any recommendations on how to do the preamp? I heard some people saw the original schematic didn't produce good results or certain components weren't working well for them.

Would you recommend me to get an OPA Alice board if I don't want to get into the weeds (though I did hear that the power supply might cause some noise)? If I were to use the Alice board it wouldn't be possible to have it in the arm format because the transistor would be too far away right?

I don't really know what I'm talking about, but I'm hoping these questions are somewhat coherent enough for me start to understand what direction to take. Thank you so much in advance!

Edit: It looks like I didn't do my due diligence in looking into the thread. I see that there have been a lot of board redesigns. Can I buy these pre-assembled and are they meant for the same form factor as the original? I've recently wanted to play around with recording music (vocals and guitar) and thought it would be a fun idea to put together the microphone too, for a low price.

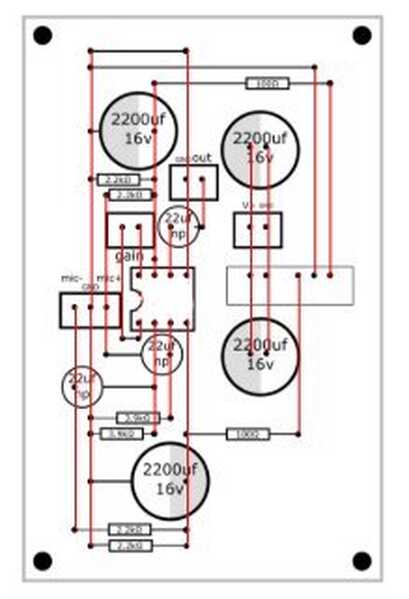

Matt and I have been working behind the scenes for some time to bring together a more detailed and modular design. Progress is rather glacial at the moment because I designed a couple of boards with their own digitiser in place to ease issues with part supplies and so on. I've stopped posting updates because I got the feeling that it might jinx things. So here's the story so far (there's TL;DR if you want to skip this):

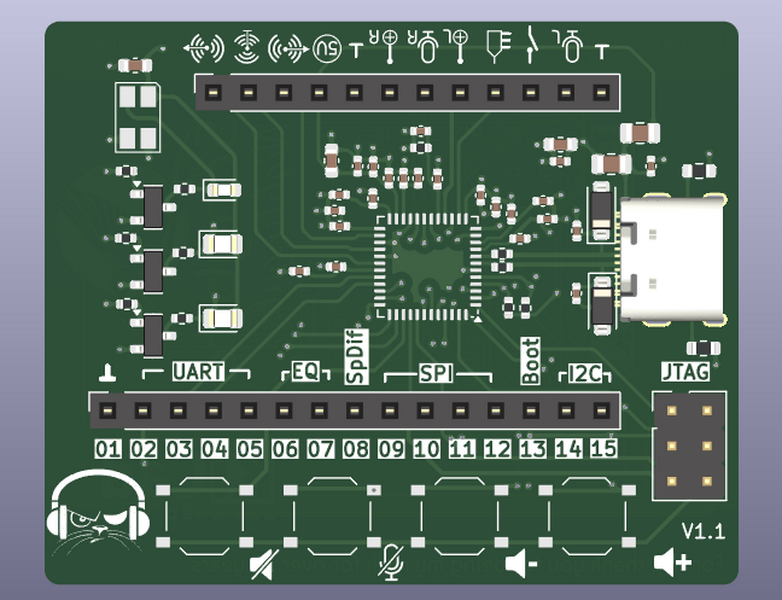

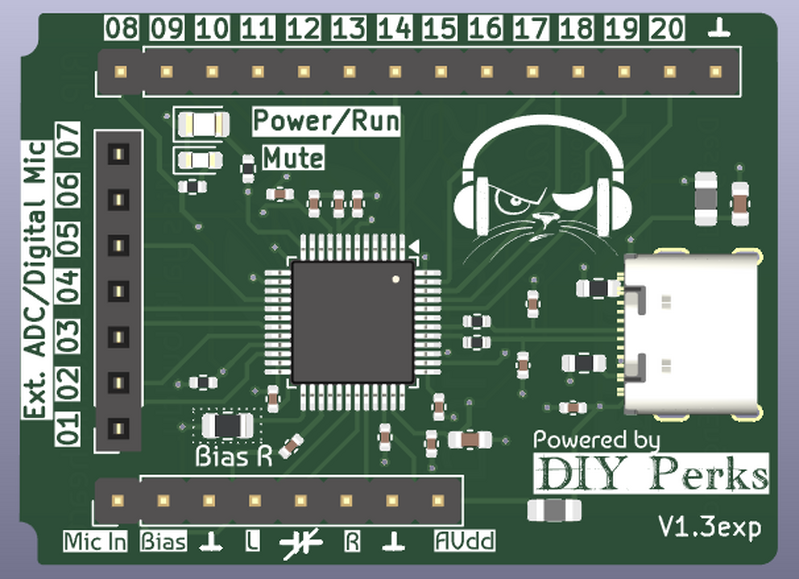

I eventually ended up with this (this is a render because it's simpler to post) on my PC:

Cmedia is a huge supplier of USB audio codecs and the heart of this is the CM6533, a complete solution with digitial audio, an equaliser... volume control buttons and more.

A complete board with every possible function you can imagine. The first prototype failed because I goofed the USB inputs (USB is quite fussy and I forgot to use the correct board stack at the last moment). But not to be deterred I fired it back at JLC and we were off. JLC is great and it came back in under a week and this time the USB was perfect.

If you google the chip you'll see that it has a small microprocessor on board (originally designed by Intel, but now out of patent). CMI offer this in four versions with the more expensive ones having either Dolby or DTS headphone for surround sound over USB.

Perfect.

Or so I thought.

But something rather crucial was missing from the datasheet that I'd followed.

If you've heard of Arduino you'll know that these are little ARM computers that we can flash with software to make them work for custom solutions like IOT, robots and so on. The 6533 is no different but unlike the CM108 (a mono codec that I'd used in an earlier, working sample) something was missing.

The firmware.

I'd prepared for this with the little JTAG (programming port) that you can see in the bottom right of this picture.

That should have been a clue as CMI didn't have any programming guidelines but I figured that some default firmware would be loaded on at the factory.

But it isn't - and to cut a long story short, it transpires that to get this thing to work you need access to a proprietary firmware programmer and CMedia don't supply it to "makers. And in fact, I only found out myself after a lot of furious googling, they'd updated one of the supplemental app notes with a single addendum back in 2022 about this.

One of its programmers did "leak" from a major manufacturer (Samson I think) onto GitHub after multiple people found their commercial headsets suddenly dying. The fix was to send it in for repair OR re-flash the firmware yourself. We have the "blob" (the binary code ready to upload) and the programmer BUT, naturally, the CM6533 isn't supported.

So a lot of loud (but private) swearing later, it's back to the drawing board, Draco! That was a couple of weeks ago now so the entire project has had to be re-designed from the ground up (again!)

It's the stuff of nightmares I can tell you 😭, esp. as I'd designed a full analogue board to operate with that chip, complete with a much better power supply that's quiet and powerful enough to run multiple op amps necessary for the extra functions we've included in the V2.

It's not a "square one" redesign but it's meant several new sections with more complex parts have to be designed, built and tested. It's all Open Source hardware but not on GitHub as yet because I want to make sure no one jumps the gun and spends money on something that might not operate as intended (or at all!)

Ironically, there's more potential for this re-design although it's more expensive than than Matt's original, the improvement in overall specification is (on paper, anyway) quite impressive.

I have a working design based on a different CMedia device but for my money it's only on a par with the original and not quite as sensitive with the small (6mm) electret that I'd included on board. It works precisely as CMedia intended and does offer the option for digital (I2S) microphones but they're all really meant for headset use - where the mic is relatively close to the speaker.

We might release a slightly stripped down version of that one later on in fact, as it's quite handy as a stand-alone but not up to snuff for high-quality audio.

I would estimate the new one (if I can iron out any bugs that crept in) will be ready in a month or so and I've worked out a way to keep the cost down while maintaining a reasonably accessible project. I've stood on enough rakes doing this to come to the understanding that no matter how much you simulate a circuit, and no matter how well it should work, a simple slip (such as getting the wrong material for the PCB) can bring one of these to its knees.

The upside of it all and there is some light at the end, is that we'll all get a true spiritual successor to the original. And the "digital" version doesn't need a screen so you can make a fairly decent mic with good performance based on a board like the INMP441 which you'll find on Amazon, Ali Express, etc. for less than the price of a cup of tea in a local cafe.

There's a gotcha with these mics though - they're all omnidirectional which means they pick up sound from front and behind. Rear sensitivity drops off a little if you mount them carefully but ultimately, the only way to really get a cardioid response (it looks vaguely like a classical love-heart shape viewed from above) is to use a pressure-differential effect mic like the JLI-2555.

Omnis are the most commonly used type for all sorts of applications including Amazon Alexas, Google assistants. They're even found in most gaming headsets where the "near field" effect is used to swamp non-local sounds (such as your mom clattering in the kitchen, the dog barking next door, etc.)

Cardioid mics work as near field (close to the source) and far field, that is a some distance from it - and this is where the cardiod and similar patterns come into their own.

In effect this means you could, if you wanted to, re-design Matt's original capsule and mount with 3D printed parts and use a I2S to USB board to connect up to a computer. I'm not planning on doing any more of these as yet and what stock I had are sold out (or solder-ED) but any new version would be slightly simpler, without a headphone amp (or at least, a "capless" one) and SP/DIF on board.

l've included an *untested* design based on my originals that should work but as it's "free" i.e. Open Source hardware, it's subject to the usual "you get what you pay for" caveats. The design includes everything you need except the digital mic board. The only real "gotcha" is when ordering you need to specify an "impedance controlled" PCB and there are a lot of options.

There's one available at JLC no extra cost that I've used successfully a couple of times now but it's easy to forget to click the checkbox and end up with something that will just fail to work. This sort of mistake isn't fixable, it means re-ordering and the cost rises rapidly. The one you need has a big red "thumbs up" on the ordering page and the weird numbering scheme does mean something but it's confusing.

This is the one you'll be looking for. I'll have a post up for this when the others go live because if you miss this step (and as I've said, it's easy to do) the USB input won't work.

This is the current version, untested but based on the working PCB, see the "exp" (experimental) version on the silkscreen, it's mostly just stripped back. The headers are there to allow you to hook up single-ended analog or digital mics, external ADCs, DACs, digital mics and so on. You can add buttons for HID buttons that control the volume, mute audio in and out at your option. The original (which came with a mic on board) was a little expensive because it was larger and slightly more complex.

I've included a PDF of the original schematic to refer back to. If you do go ahead with this one, you will need to refer to the schematics for the correct pin numbers because the ones on the silkscreen are numbered for ease of reading. You can find more information from the CMI108B's datasheet which you'll find with a simple web search. I have to be careful reposting stuff as it's copyright and I'm not in CMedia's "nice list" right now. 🙂

As it stands you can get lower cost generic USB-audio devices (some based on this very IC) but most or all of them don't run out the external interfaces like this, in particular the I2S ADC and DACs so this board is useful to makers who lack the skills to design their own but want to experiment with pre-made ADCs and DACs from people like Adafruit, Sparkfun and others.

Of note here is that the BOM includes the jumpers (which you don't need to get from JLC) but the USB-receptacle is not selected by default and you DO need this as much as you MUST use the board stack I've specified or it's pretty much guaranteed not to work. Mounting rails are added at JLC as this board is slightly smaller than their new minimums (70mm) - this was a new one when I tested to make sure the BOM was correct, JLC, like most manufacturers, constantly upgrades its stuff.

What struck me as weird is that the USB-C connector (it works either way up) means that one of the USB lines is slightly longer than the other sometimes - it depends on how you put the plug in - and that should throw the calculations off but oddly enough it still works. I don't have the necessary test gear (because it's hideously expensive) to see the signal "reflections" due to the impedance mismatch. (See here: https://www.test-meter.co.uk/data-network-testers/time-domain-reflectometers-tdr)

As a designer, I've found by painful failure that USB can be very twitchy indeed - so I'll probably revert to a USB-micro B on the lower-cost board as that's not an issue. I'm using USB-C on the premier models because it's more compatible with future hardware and the connectors are more robust.

These are the files you need to order from JLCPCB - it's pretty painless but watch you don't skip Impedance Control in the PCB options as it's almost guaranteed to fail

TL;DR

As of this writing, I'd advise holding off if you want the fancy one. The smaller one should be fine though. It's Open Source but watch out for that rake I've mentioned a couple of paragraphs up. This one should work fine with an analogue source fed into it's analogue mic port a little like the one Matt used in his original design (but it can only do either digital OR analogue, not both at once).

I can only guarantee boards that I've personally tested until they break and each iteration has to be assembled and tested in China and the UK which is quite a long winded process. Tax and shipping more than doubles the cost for a rapid turnaround too.

I've also developed another new power supply board for the NMA0515 (for people who have the original with the noise pass-through we find on a lot of laptops in particular). This is something the NMA0515 isn't designed for this and a noisy USB-source will totally ruin your day since it bleeds right the way through to the output. Took me a few revisions and a lot of frustration to finally figure that out. My own laptop whines terribly with that part and it's a bind to get rid of since it's right in the audio band.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco Great work, seems like a LOT of effort! I can't wait until it all comes together! I would agree, although more common, I don't think omni mic would be the best for this product because this is supposed to be for an office setting (home or in-office), and it would more easily pick up keyboard sounds and other people around you.