Yeah, that's the REAL problem with an omni, particularly one that's meant to be operated a few inches (30-60 mm) from the speaker to be comfortable. They're fine if you're "on top" of them so to speak (note how office and gaming headsets invariably have a boom to position the mic right in front of the speaker's face. Compare that to a lavaliere (tie-clip mic) which is designed to be used cliped to a shirt or somewhere it's not that visible.

Most lavs are omnis (because lavs are usually cheap and pressure effect mics aren't) but the way sound tends to move through space and the person's body to some degree, counters that effect a little.

Omni's have a place of course. The Sabrina referenced above was originally designed as a tabletop (pressure zone) mic which is for conference or tabletop use when you need to record a bunch of people and you don't want everyone hiding behind a mic. Crown owns the rights to the name but if you've heard (heard, geddit?) of the boundary effect it's essentially the same thing. If not, try speaking really close to even a cheap mic and you'll notice that the bass increases quite a bit.

Boundary mics utilise this effect by allowing sound to enter via a tiny port at the front which is almost hard against the surface of the mount which has to be hard (see above).

Pressure waves get trapped between the surface and the capsule and we get a 6dB boost for free which is neat. Even with the 20dB gain offered by the CMI108B, it was still too quiet for the intended use so I'll revisit it some time and put a small amplifier on there to compensate. Boundary mics are a little special for DIY Perks but there's a still a call for them, so I might just make one without any gain to go along with the final V2.

There's also a ribbon mic that I have designed but have been too busy to complete. That one is very difficult to build and as careful as we might be, the requirement for razor blades - not razor sharp knives, I MEAN actual razor blades probably puts it outside of Matt's purview. We don't want someone slipping even though I made the thing safe...er (safe enough because I know the risks) and I can make it safer still, but there's still the issue that someone needs to load a couple of very real, very sharp, "safety" razor blades into the cutter.

Each pair of blades will typically cut one or two ribbons before having to be replaced. The manufacturers of such devices have very skilled people to do this we have... ourselves. To date I haven't come up with a reliable method to produce them quickly, easily and (above all) safely. They are only a few millimetres wide (1/8" or less) and 30-40 milimetres (a little under 2") long. Try that with some chicken foil and a pair of scissors.

Not impossible but not easy, right?

Now take that foil and imagine it's 2-4 microns thick. Mom's everday kitchen foil (the stuff you find in the supermarket) is as much as 10x as thick with the everyday stuff being more than twice as thick as the thinnest foil.

And then you have to crimp it with corrugations at roughty 12 bumps per inch. I don't know the term so bumps will do. 😉

And then (oh yeah, not finished yet) you have to pick it up - and if the hamster the opposite end of the room gets hiccups, it'll blow it across the room.

Now you have hold of it you have to mount it (and so far as I know this part is ALWAYS done by hand) between a pair of super-magnets with around a 10-20 micron gap at each side.

This is something that might interest you actually. My 3D printers are inoperable at the moment but it's something you might want to consider. The cutter is particularly troublesome as I've mentioned, the corrugater is just a couple of loosely-meshed gears (better to feed the foil through in its paper actually). I've done that in plastic but metal is just better I find as it doesn't need constant adjustment.

The motor body (you'll find lots of examples online) is the most difficult part due to the proximity of the magnets to the workpiece and it has to fall between them roughly in the middle (ideally exactly).

Designing and interlocking slider seems to be the way to do this. I made a square when I was a nipper in training at a factory. That has one so the slider just mates into the handle and doesn't fall off but can still slide up and down. I couldn't get my 3D printer close enough but I would imagine that it's quite possible - and the tool could be made up at one of the 3D houses (JLC, etc.) in nylon or some other tough and slippery plastic.

A pair of set screws could be used (well, a single one with a sync. gear) for each side to close the magnets together after the foil is mounted would make things easier.

I haven't see one done this way, but that doesn't mean such things don't exist (and if not, I can't patent it and make it Open Source) and once I press send, that makes this "prior art" and a patent could no longer be asserted unless it's already granted. There's a story behind my utter hatred of patents for another day.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

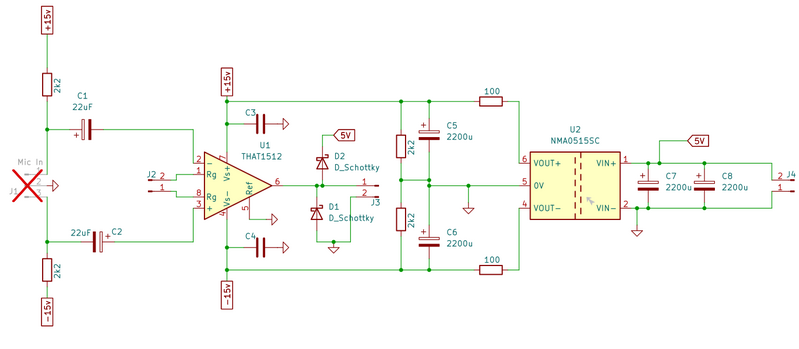

@dunkan77 (Link to what I am responding to: USB-C Microphone (official topic) – Page 34 – Microphones & Mic Preamps – DIY Perks Forum) Damn I think my THAT 1512 was also a fake, I got the same voltage readings of 10 and 8 on V+ (pin7) and V- (pin 4) to REF (pin 5) with absolutely no audio... Does anyone know if this is a confirmed way to identify a fake THAT1512?

I can't say with 100% certainty, but its plausible if you got one from Ali Express or some other Chinese re-seller on eBay. They are often as much in the dark as you and I are. I've been through a bunch of them (and some 1510s) and all of mine worked so without a "possible fake" to compare with, I don't have a reference.

Usual way to debug this is to measure the voltages at Pins 1-8 referenced to ground (which is also on pin 5). Also check that pin 5 connected to USB 0v - with the THAT remove from its socket and again with it plugged in.

It's one of those problems that's a doddle to identify if you have access to an oscilloscope but a nightmare if not.

The THATs are very high gain *wideband* devices and as such signals outside of the audio range can drive them hard. So hard that the NMA0515 will run out of steam and the supply voltages will collapse. Worse if this is the case, the output voltage (pin 6) will reach a level that is almost guaranteed to destroy the digitiser. A simple digital voltmeter won't be able to display this as they aren't fast enough to follow the signal.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

Just started my build! Haven't acquired all the electronics yet... Mostly playing around with altering the mounting system to be more compact for a more... Thematic concept.

Currently I have the recommended JLI-2555BXZ3-GP condenser. I've been slowly reading through the various responses on this thread and now I'm a bit confused as to what version of the board I should be focusing on? Is the original design still referenced in the build guide recommended or should I go for some of the updates made in this thread since? Should I wait for @marcdraco to release the fabled V2? I would like the microphone to be versatile but stay relatively easy to solder since this is my first soldering project.

Regardless, here is my concept... A compact shock mount crafted from a 2½ inch conduit lock nut, with the mount held within the jaws of a bobcat skull (an antique I am currently heavily degreasing in ammonia). Until I finish the custom housing for the condenser, I'm using a small 2" tea ball as a stand-in for visualization. Hopefully the relatively small shock mount should yield acceptable results... I'm trying it out with simple hair ties until I get a better idea of gasket sizes. Here is the current state of the shock mount and the original mockup in the not-quite-finished skull.

Welcome @bromatolite! That's looking like a really cool concept.

The fabled V2 ( 🤣 ) is still in development. I ran into an issue with the digitiser CMI6533 (it has an internal MCU and CMedia won't release so much as the programmer, let alone the firmware!) It's not clear (and CMI won't say) why the firmware wasn't pre-loaded, but it's set everything back a while. A rather important detail that you'd think would be mentioned in large, bold letters on the datasheet. But nope.

That was an expensive problem, so it was back to the drawing board.

Really quite depressing but things are moving along. I'm deliberately not posting updates with every design in case I miss something and I'm already over budget, despite working to keep end-user costs down!

I just received the latest preamp modules and I have some more testing to verify they are all working correctly. The full V2 is quite complex but more modular with a choice of SMD only or through-hole using the semiconductors from the original build so it's a very versatile setup. In hindsight, I could (should) have done this much earlier but it's an iterative process and hindsight is both expensive and 20:20.

There's nothing fundamentally bad with the original design, but Veroboard can be tricky to work with since it doesn't have a solder resist layer. The JLI capsule is excellent - Ali Express usually have them in stock and they are quite easy to see as the "cheap" ones have a gold finish or a blue back. Visually they are quite different to the real McCoy.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco Yeah, I'm excited for how it'll turn out! I'm wondering how compact the electronics could be... I mean, there's always room in the brain case for some wires 😂

But yeah, I believe you stated before that the microphone capsule assembly will be modular between iterations? So the capsule+transistor+housing+lightweight shielded cables will be compatible with the various "circuit box" configurations? For my purposes, as long as the "head" is cross-compatible that helps a lot in terms of eventual upgrades to the circuitry. To that point, would you recommend I wire things so that the capsule assembly has a grounded jack end so that the circuit box can be switched out?

I think for right now at least I won't be making a custom arm. I'll just pretty up an existing microphone arm, so having the cable be separate might be good for long-term maintenance.

And instead of veroboard should I print one of those custom PCB's? Or do you think the board will be good practice? It's not super compact, but I suppose for my first project like this it doesn't have to be.

Thanks for the help!

Oh darn. Wordpress logged me out right before I hit send and I lost the whole reply.

It's a conspiracy, a conspiracy I tell you.

Stick with Vero for now, the new ones are designed to work with the existing capsule design so that won't change. Just be careful mounting your JFET, those little wires can snap very easily. I've done a few different capsule adaptors that are simply JFET mounts like Happy and Woody "Hammerhead". They're pretty low cost from JLC as you can make them up yourself at home, even if you use one of the alternative JFETs.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco Thanks!

Just started collecting parts in a shopping cart to order. Haven't added the items for the rotary switch, but could you confirm these pieces are correct? And do you have a recommendation for a 500ohm potentiometer instead of the rotary switch with 11 resistors soldered to it? As well, is it absolutely necessary to order the 2N4416 separately from eBay or is there an alternative still in production that I could order on digikey?

https://www.digikey.com/short/8thj4m74

The THAT1512 seems to be only available on EBAY, right? And if I don't need to change connection to USBC for the output, do I need to modify the adapter?

Also, I just noticed the XLR option some people talked about. I could get a used XLR audio interface for the same cost as the USB adapter alone. Would it be easier going for the OPA Alice + interface combination?

Ah, the poor 2N4416, how we miss you. There are a few that will do the job, my preferred JFET is the LSK170, it's available in several "grades" - the B is probably closest however. I suspect the A-grade won't work with the original due to the current demands (but note that I haven't checked this). I'm flat out trying to get my workshop tidy so I don't keep stepping on stuff (particularly 13 A plugs). You can tweak Matt's design to work with a whole bunch of different JFETs so long as they have a low(ish) Vgs off (less than 0.5V ideally). The 2N3819 is still used in a lot of mics but the resistor (2k2) values would need to be changed. The 170 should just drop in and work.

OPA Alice is a completely different animal and drives XLR directly (as do several of mine) but as I recall it's intended for P48 phantom which you only get with higher-end interfaces - generating 48 V from a USB connection is quite tricky (to put it mildly) but if you can source one, Alice is a great mic and it's got quite the following. You can even get the PCB from several suppliers, pre-made if you want for around £40.

V2 is a complete, ground up re-design with far more features than exist anywhere in the Maker space - not least with a USB-C receptacle on board. You can still use XLR connectors to the capsule, if you want to go that route of course. The same applies to Matt's original actually. That's the great thing about DIY (and DIY Perks) you're not beholden to any given design paradigm once you have the basic components working. XLR, USB micro-B, USB-C ... you name it, anything is possible. Matt's design is just beautiful and that's what inspired me to go one (or two) better - but I'm a big fan of his channel and ultimately this remains his project. I'm just having a ball learning (unlearning stuff from the 1980s) and catching up with CAD and multi-layer high-speed digital that simply didn't exist when I was training. A typical Arduino that most Makers would chuckle at for being slow is faster and has more memory than the machines I used to write games for!

All the better mics use a differential lines to eliminate noise pickup issues (I think I covered how this works) - but if not it will be in the book I've partly written, but had to shelve temporarily while I completed the re-design.

There are things V2 does that would make Alice blush. (Ooo err missus) and it runs from USB without the need for a 48 V phantom supply just as Matt's original.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco Thanks again for the clarifications! And sorry for the bombarding of messages, it's just nice getting support like this given this is my first project of this type.

I think I will add the LSK170 to my order. And just confirming, the other parts in that shared cart I posted look ok? Is there a difference between different resistors of the same ohm rating?

And then if I get a 500ohm potentiometer instead of switch, is there an ideal power rating for those? I see 5W, 2W, etc... I'm guessing it's very low power draw in that part of the circuit, so maybe a lower rated potentiometer? That's a circuitry aspect I am not familiar with. I just know I tend to like continuous adjustment as opposed to rigid levels.

But thank you so much, I think once I am sure of the exact parts I should order I will begin work on the V1. Maybe next year upgrade to V2 if the plans are finalized then. Do you think it will be another veroboard, or will the V2 be one of those printed style boards you have been prototyping with, available for purchase to support your work?

Sorry, I forgot about the gain control - that's on me. I can't see your BOM - probably a limitation of the cookies from Digikey.

Don't worry about asking for help, that's what we're here for. We all help each other - I just happen to be eyeball deep in microphones and high-end audio. As I mentioned things changed quite a bit in the 40-odd years I was absent from the trade/hobby. I became a tech writer because there's less math and I get to talk to smart people - very, very smart people - and then repeat what they say in words we can all understand. 🙂

A 500R (R = ohms) pot is certainly an alternative but it's tough to get the position just right and you do need a logarithmic taper. The problem isn't with a pot, it's with the way that the THAT (and similar parts) work. A digipot is an option that I've considered but they're even less accurate unless you spend silly money and they need an MCU with I2C/SPI to even work. If you don't know what that is, don't worry, we're not using them.

Resistors are simple devices but there are a LOT of options: carbon (you don't see these much now), metal film, thick and thin film, wirewound, etc. With tolerances (how close they are to stated resistance) from 20% (!) all the way to 0.01% if you have the funds. Most common ones these days are 1/16W (power rating) in a 1% tolerance which is more than enough for all but the most demanding of jobs (instrumentation and medical). I can't think of anything in a mic that needs better than 1% - even if you're making a the instrumentation amp block from three-amps (an alternative to the THAT1512).

As a matter of reference, if you make a resistor network of 2 or more resistors of 1% tolerance, the entire network also has a tolerance of 1% - handy to know if you get into designing your own stuff - something that I'm aiming to kickstart with the book (which will be either free or very low-cost for the "paper" version). It won't replace a good beginners book on electronic theory (there are loads of those) but it does go over a lot of the pitfalls, landmines and rakes I stood on - particularly when coming from single-sided through-hole technology (THT) parts to SMD.

For audio work we really *should* use thin film for reasons that are beyond the scope of a simple discussion but the thick film ones are quite adequate and can easily be upgraded when you order the boards from a PCB house like JLC or PCBWay. Even then, the majority are in non-critical sections so you only "need" to upgrade the ones that are in the low-level audio section - that's the input to the THAT for example.

You don't have to use a THAT1512, the 1510 is almost as good and can be found at a much lower price. There are others like the SSM2017 from Analog Devices which are all-but drop in replacements, the resistor chains are different though - but it's all in the datasheets.

If you do opt for a potentiometer, look at the application notes to make sure it's sealed (any crud that gets into the track will make it pop and crackle over time).

The only parts of Matt's original that are under any "stress" (and that's pushing it) are the 100R parts that form part of the DC filters, but the capacitors charge relatively quickly so there's no chance of them going up in Magic Smoke.

You'll be able to send me a PM soon or just drop an image in if that's easier.

V2 is on multiple PCBs - each one is a module so you can just get what you you need for a given application. The mainboard has the digitiser and some glue logic but the power supply and pre-amp are all separates and I'm investigating the potential to do Vero versions of those that will, similarly drop into the motherboard. Performance with Vero (or A. N. Other Chinese copy) won't be as good as a custom PCB because the PCB has four layers - two of which are dedicated to keeping noise and signals where they belong - on the board; and other signals out.

You don't need to use the mainboard and digitiser unless you're doing the full thing. I just need to sort out a better regulator design for the THT version.

My GitHub repo. has a very cost-effective experimenter's board (Claire) that you can have as a two or four layer version with hundreds of solderable points and some buses to carry the power. It also has space for a single SOIC-8 IC on there so you could use some ICs that simply aren't made in THT - and never will be. SMD parts cost less to make and every penny counts in this business. They're smaller, better for machine assembly and often more performant than the THT equivalent. Hand soldering them is possible - but difficult on the smaller ones like 0603 and 0402. I'll look to do a "bare" SMD board from the working designs with larger parts for the home constructers.

Here again, the mainboard is the big problem as it's got a bunch of very dense, very small ICs on there that aren't for the fainthearted. I learned to solder (badly) before I even hit in my teens and professionally trained in my late teens and even I don't enjoy working with them. This sort of stuff is best left to people with the right gear like a reflow oven or nerves of steel and a very fine-tipped soldering iron. One mistake might be an annoyance or it might destroy the chip and everything around it.

EDIT: just for fun, you might have a look at Paul Falstad's simulator. It's not 100% accurate (not even close as some pedants around the web are keen to point out) but it's clear and easy to use. And free... did I mention that? https://www.falstad.com/circuit/

There's loads of sample circuits that you can play with an it's a LOT easier than any other simulator I've played with. Drawing is a little fiddly but you get used to it. LTSpice is easier to lay out schematics in and far more accurate, with plenty of parts modelled but it's not as accessible for a beginner. The 10 ton gorilla is Microcap 12 - Freeware, you'll find it at Archive.org but it's a behemoth that assumes a high levels of competency from the get-go. KiCAD also has a simulator but it's very limited so I tend to use it for schematic capture and layout - everything I do is produced in KiCAD and it's superb: if the circuit works, the board usually does - and if not, that's because I did something wrong that the internal checking isn't design to pick up on. (This is a limitation all of the freeware simulators suffer from - because they can't model how the electric fields move through the circuit. Basic field theory is something I've spent a lot of time on in the book because it's often glossed over in textbooks (if they cover it at all) and until you think in fields, your boards won't be optimal, if they work at all!

I'll let you in on a secret. The energy in your circuits isn't in the copper, it's in the plastic (fibreglass). The fields move the electrons, not the other way around - the copper traces are simply there to tell the fields where they need to go. It's a bit chicken and egg, but trust me, this is how it works once the signals start to get above a few KHz. And digital works in the mega->giga Hz due to the way modern components are produced. Chips are getting faster all the time as a result of "die shrinkage" - it's just a side effect but again, this is quite a complex topic so I won't go into detail here.

I can recall a time when 1mS was fast. We're orders of magnitude faster now with anything switching in >4 nano seconds (from 0 to Vcc or back) being considered "slow". A fast chip these days will generate square waves that transition from 0 -> 100% in a few 10s of picoseconds. It's nuts and the side effect of this is we have to design with these speeds in mind, even if the MCU is "only" running at a modest speed of a few MHz.

If you have a modern multimeter with a NVC (non-contact voltage) point, you can see fields for yourself by plugging a "kettle" lead in at the wall and switch it on.

If the energy was in the copper wires, there's no circuit so no electricity... but in fact, the instant you switch the socket on, the two fields race from the wall and reach the end of the wire at around 2/3rds the speed of light. The NCV port has a sensor in there very much like a microphone with a MOSFET to allow it to detect these signals as they hang into the air. Without this effect, we wouldn't have radio or even light to see by. It's enough to boil your noodle until you see it happen.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco Sorry, took a bit to get settled in after work and re-review the digikey parts order. Here's what I have so far, with part type/#:

I actually ended up ordering the THAT1512 and a pack of the 2N4416 JFET's off eBay. To that end... I am going to have 7 extra Motorola-produced 2N4416's, so if anyone wants one I'd be happy to send them one if they pay the shipping cost.

But I think everything on my list is alright. Took your advice with the 1% variance resistors. Separated the potentiometer and last resistor because that is what I am thinking of running in series as a replacement for the rotary switch.

Also... no clue which kind of breadboard/stripboard I should pick on DigiKey... Not sure if that's the right place either, but I don't know which product # would be the best for my needs for just a single board. Any help with picking an item # would be appreciated, or a recommendation for another place to get it would be nice.

Thanks!

DigiKey is one of my suppliers of last resort. I don't have an issue with them (it) but I don't order enough bulk electronic parts to justify the shipping usually. Most of my stuff comes pre-assembled from JLC because the China supplied parts cost a lot less overall and most are OEM, except stuff that's been around forever like NE5532 op amps that are cloned by any number of players.

I like eBay for odds and bods that I need and Ali Express if I'm not in a massive hurry. Ali is useful for bulk parts that are sometimes tricky to find at a decent price here. It can be hit and miss, of course, and I've been "bit" more than once.

I'm counted as a hobbyist, so I'm in the same boat as everyone else trying to cobble together a BOM.

A major issue with Veroboard (stripboard) these days is in the name. Vero, like Hoover is a trade name of the manufacturer. ( https://en.wikipedia.org/wiki/Stripboard).

Since the patent is long expired, loads of companies make the stuff but a lot of it is 💩. In an effort to maximise profit, the SRBP (which is a mouthful even as abbreviated) is often paper thin and the adhesive holding the tracks in place is poor, not to mention the copper foil is almost atomic.

Original Vero isn't "thick" (it's 1.6mm standard like many mass-produced PCBs) so it's study enough to withstand the intended use of prototyping work an can withstand some amount of rework before it fails. The non-Vero stuff not so much, so this is really a case where it matters to get OEM. The Chinese stuff is so bad, I've seen boards snap during shipping and hairline fractures in the copper can cause troublesome problems that are difficult to track down.

Things like capacitors and resistors can be found on eBay (and even Amazon) where you can find boxes, "Bojack" I think is one, with hundreds of parts sorted by value, for under a tenner. Might work out better for you than Digikey prices which are pretty high, but then they get you with the shipping. These are great if you want to tinker with different values.

Non polarised caps, for example, can be made with two polarised ones in series (note you have to double the required value as capacitors in parallel are the opposite of resistors. The calculation is fiddly, but two identical parts work out at 1/2 the value so for 22uF you'd use two 47 uF. An interesting upshot of this is you can use a lower voltage rating so what you lose on the swings, you gain on the roundabouts. Two 16V capacitors wired in series have a total voltage rating of 32V because the load is shared. It's sometimes more cost effective to do it this way if you have the space (16V is a bit tight for a 15V supply, esp. if it's not regulated). For the NMA0515 (which isn't) I'd suggest the 25V ratings for singles or two x 16V parts back to back.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco Ok, now I'm a bit confused... So your preferred option is going with custom fabrication from JLC? And I don't need packs of each item, the final cost of the electronics from DigiKey (for the order I laid out in my spreadsheet) is $13.74, plus about $6 in shipping/tariff fees. So right about $20 USD. I don't think I need duplicates of most of the parts, so is that an ok price? It doesn't include stripboard yet though.

If I order through JLC and get a custom board with components pre-soldered, is it going to be cheaper? It'll also probably be better than the imperfect beginner soldering I'd be doing 😅

@marcdraco you do have plenty of board files on your github... If I wanted to recreate the V1 with a printed board, which one of those files would be appropriate? Would that theoretically lower the costs/make it easier for a first-time crafter? With all the components on JLC, should I order from there?

@bromatolite Honestly, not really. They're OK but state of my art has moved on a bit. Those were experimental and while they work, they're far from what I would consider good enough. I tried my hardest to retain some level of backward compatibility but ultimately, something had to give if we were to make the new one so good, it's going be worth the wait (and it's been a LONG wait).

I can PM you a file with the current pre-amp module (you'd have to order two boards which is the minimum) but I think the BOM is up to date with the correct parts. (Sorry everyone else, you're just gonna have to wait, I'm using Bromatolite here as a guinea pig 🤣 .)

If nothing else, you can use these files to decide if it's worth the cost. I tried them today with an electret capsule I found at the bottom of a box of Crackerjacks - they get everywhere now and much to my astonishment, it actually worked surprisingly well, with the preamp clipping hard against the 5V rail when I was just speaking in a normal voice at about 1M away.

That's right folks, this one is 5V with a -5V to drive the INAs. I still need to test a THAT1512 with this configuration but I've been at a mate's trying get Nobara Linux to play nice with a 16 core Xeon with an nVidia card in it - connected to a 720P TV. Quite a weird setup - and I gave up and figured best set this up at home so I'm not getting annoyed at the virtually useless display I'm faced with. To be fair it was given to my elderly friend for free so I shouldn't complain. But imagine trying to set a modern OS up on a screen that refuses to come out of 800x600!

Bear in mind that the alternative PSU module (based on THT and with the NMA0515 so people with the original can recycle theirs) is still under heavy development. Truthfully there is so much wrong with the way USB delivers power (and we're supposed to limit the inrush current if we use more than 10uF). Matt did use a large capacitor but most systems can cope with that - some won't, but I've yet to hear of one. When USB was designed, the designers allowed for noise rejection on the data lines but didn't give power a second thought. That's easy enough to deal with inside a digital IC that has the headroom to lose a couple of volts to squash line noise, but add a JFET and x800 amp into the mix and things get tricky, real fast.

Since I'm more pedantic about stuff like that, I'm looking to do it (cough) right (cough) per the official USB specification which is more work for me, but better for everyone else. The preamps are due for a minor update, so the mounting holes are sated to move but that won't affect you directly unless you want to come back and make the full system later on.

Now I know how much current the boards are going to need, I can match up the power filter more accurately. Caps are great but inductors are better with one, teensy-weensy little snag. The output impedance (that's the amount of current drawn by the circuit) directly affects the filter response; at light loads that can mean that rather than reducing the 1KHz USB whine, it actually makes it worse!

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco I've been following this thread for a while, and it seems like the coveted V2.0 mic release will not be much sooner than when Project Binky will be finished 😆 I can't push myself to make an original mic just because it seems like there are some better versions of a design, even if "better" means it's really more like beta versions. And as I can see, there are a lot of people who like to make a microphone, but after reading this whole thread either confused about what to do or just waiting for V2 release, because it will mean that @diyperks will make a video with detailed instructions.

I'm not really deeply familiar with circuit board design, but I very much like to poke things with a soldering iron. Shunt-modding GPUs, making and modding keyboards and mice, resoldering EEPROM chips from a broken monitor PCB to a working one - that kind of stuff. But my dad repairs complicated devices and makes custom ones, mostly within the Hi-Fi segment. He makes money that way.

So, I had an idea for a while, but finally decided to ask about it only now.

What if within dozens of your designs on your GitHub, there is some combination that can be described as a V1.5? I'm not expecting those to be perfect; they are prototypes after all, at best in some way backwards compatible, if even that. But I can run those designs by my dad and see what he will get from them, maybe he will spot some mistakes, or find something to improve. But eventually, if everything goes the way that I imagine it will go, we will have something like a transitional variant of a mic design. I will order parts, PCBs, assemble all that, and make a document describing the process of building a mic from the perspective of a novice. And this can be used later to pass on to people who want to try to build something now.

I will (maybe) get to make myself a microphone. Other people will get a reference to help them make a decision or to build something. Win-win, eh?

If you think that all of this nonsense is not really worth doing, no worries, just ignore this wall of text. 😀

V1.5 was (is?) a complete unit but I'd hardly describe it as the "ultimate" although it is complete with I2S in and out (for digital mics). That intermediate version combined a simple mic amp and a digitisier so there's no extra bits to buy, short of the capsule parts. It's not on GitHub though as it's becoming a distraction. All of those can be considered experimental trying out solutions (many of which went against my better judgement like split ground planes).

The issue I had been trying to solve wasn't where I thought it was after all. Everything I'd read up until relatively recently led me to believe (believe being the operative word) that the whine plaguing this thing was coming from the NMA0515 -or- the test laptop which didn't make a lot of sense. Cut to the chase, it's on the USB power lines: a 1KHz square wave (it's not as obvious when the thing is in circuit due to filtering effects of the other parts) but it's there.

In design, it's a huge no-no to run "noisy" lines - digital or high-level analogue - near to each other as the signals from the "aggressor" couple on to the "victim" and ruin everything. A digital board will either only work sometimes or not at all, analogue designs just make horrible noise. And what does USB do? It mixes the power and high-speed digital on the same cable - and that bleeds all over the very sensitive microphone inputs.

The usual way to dispense with such an annoyance is to put a large filter cap on the input but the USB specification disallows anything larger than 10uF (without a slow-start to limit the "inrush" current). It's a bit like bursting a damn as a discharged capacitor looks, for a brief period, like a short circuit.

There are multiple versions there to suit different use cases, some of which were created because there are places in the world where the THAT's simply aren't available so I did a some based on Doug Self's design from 1990s which is almost as good and costs less. Same with the modular parts but they were done that way to keep my production/prototyping costs down as low as practical.

The 1.5 "Sabrina" was so good (that I moved to a more complete one based on the CM6533) where a simple mistake (wrong board material) blew the whole run and then the horrific realisation (followed by months of back and forth) with CMedia, JLC and LCSC trying to figure out who was to blame over the lack of firmware in the 6533.

Have a read of the datasheet and nowhere in the current one does it mention that this is requires licenced firmware to run a basic internal DSP. No firmware = no worky. I've mentioned before I think, that it is mentioned in some product data at CMI's site, but it's not in the official datasheet even POST 2022 when it was first recorded.

Well thanks for nothing CMI! Probably 100+ man hours trying to figure out what was wrong only to find out that I needed a programmer that they won't supply to end-users. It's clear they're trying to keep "makers" out of the USB audio space.

So back to the chalkboard again ... but as a result the new ones are considerably better, even more modular and more versatile. There's a lot going on behind the scenes that's not (yet) open source as I don't want someone beating Matt to the punch after all his support during this development. If I let on what's really happening some other channel could get in first.

Quite a lot of stuff is working but "secret" since the Starfire series. The original versions also used a rather hokey way of biasing the FET which I was never really happy with so I've gone back to a more "conventional" method which offers even lower distortion from available JFETs.

The "simpler" capsule boards are more suitable for most builds, the P48 ones like Varee are great and all but the extra parts add in background noise that cannot be avoided and frankly, the (albeit bulkier) OPA Alice board is quieter.

The two things to watch out for are ground loops ("star" grounding helps but it's a bit of a hack) and that 1K whine on the USB. A beefy input capacitor should be enough to rid yourself of that (unless your dad is up for modifying a slow-start). Slow starts are pretty easy usually but when you're mixing digital and analog with power conversion chips, some things have to "start" at different times. The digital circuits generally come up without issue but power converters like the NMA0515 have fairly lusty current requirements and without an "enable" pin things get a bit more tricky.

These are the things you only get from experience (or a Masters level course from someone like Dr. Eric Bogatin) and mixed signal boards come with even more gotchas and the V2 is ALL mixed signal.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

Hi @marcdraco, I'm new to electronics outside of my specific niche and I'm terrible at soldering, so the 1.5(ish) version you're describing with the capsule parts leading into a bought preamp and digitiser sounds more something up to my skill level. I appreciate that it was becoming a distraction to you but I thought it would be worth asking if you could point out where in the thread you discussed it or what parts were considered.

Thanks very much,

J

Hi J and welcome to the forums.

The intermediate V1.5 (a tongue in cheek reference to one that's better than the 1.0 version but not quite the V2.0) was born from the ashes of several digitisers that I blew up developing the V2.

Entirely my fault for assuming that these things had input protection when they often don't, it's a standalone digitiser module with a USB-C connection but I felt that the microphone's sensitivity was poor, even though the reference design is for a headset. I don't think a gaming headset is worth making at home but it would certainly do that, you'd just have to add a donor unit, even an old pair of over ear headphones.

Following that I figured I'd go for gold and use one of CMI's more advanced chips so makers had a really spiffing headset adaptor.

And... that's where I got mired in proprietary licencing and ran into a wall. The CM6533 is sold quite openly to makers and as an advanced headset digitiser with some rather nifty features - including Dolby or DTS headphone. The "N" version which is the one most people carry only has some basic tonal controls but what they fail to mention is this: they come without the firmware to make them work.

And to get the thing to work you need not just a specific programmer, you also need the binary "blob" which contains the actual software. And for "reasons" CMI won't even talk to "makers" let alone supply the necessary hardware, binaries or information on how to set them up. So my best digital design (which otherwise works beautifully) ended up as a very expensive white elephant.

Matt and I discussed the resulting issues and as a result a phoenix was born from that pyre, making the V2 more modular than I'd considered. Some of the early prototypes are back from China now with some more due to go out soon. I'm leery to put the design files out there for the full V2 yet because I don't want people wasting money on something that's not quite right.

A major issue that I've identified with USB audio for high-performance is that USB power is noisy but for a reason that I'd never even considered. It's reasonable to assume that a lot of high-frequency crud is coming down the power line from the computer, what I failed to notice was that USB produces a very nasty whine on the power rail caused by the "polling" signal it sends out every 1000th of a second.

During the development of the V2 I'd always assumed something was amiss with my design (I'm a bit of a pedant when it comes to following the official standards) which call for no more than 10 uF bulk capacitance at the device. A bulk capacitance is there to buffer the local circuit in case it demands a lot of power very suddenly. And that's all it does.

Long story short, 10 uF isn't close to enough to filter out large spikes in the power rail such as the ones caused by USB's polling pulses.

I tried a lot of stuff on the bench to filter the noise but every single prototype failed on precisely the same issue because I designed the testbed stuff with a bench supply but the prototypes on an computer. A rather blinkered approach where I'd convinced myself the fault was elsewhere and not at some fundamental level. Another way of putting it, I was so deep in the forest, that I couldn't see the wood for the trees.

Digital chips, and this is a nature of how digital works, aren't affected by the power line to anything like the same degree as a "naked" analogue pre-amp is. Matt used very large input caps to fix this but they're strictly against the design guidelines and I stepped right on that rake!

So I've been trying every trick in the book to solve this issue while still keeping it "legal" but that's also had a side effect of making the final designs more "mix and match" which is far better for makers with the digitiser module gaining a very simple, but robust input protection. The final prototype (rev 3) will go to JLC with the next batch, I'm just in the process of finishing off the main (but still optional) section because it's rather complex and I want to get it right before I drop a bundle on production. My beer fund is looking a bit dry these days 😉

It's all worked out well in the end and soldering this thing together is mostly a case of dropping in 2.54mm pin headers and sockets which is very straightforward indeed, made a LOT easier by the solder resist layer on the board. This causes the solder to blob up around the joints rather than short them. You still can foul it up but it's a lot easier than Vero. So much so that a couple of the modules are will be available in through hole (THT) or SMD. SMD performs a little better and the THT designs are cramped, but the bare boards are a good deal cheaper than pre-assembled ones.

Having pin headers/sockets allows for pluggable modules (like a RPi "HAT") that you can put together like Lego bricks or just use Dupont leads. I expect you'll be able to buy the modules with headers in place but I haven't priced that or checked to see if the sizes I'm using are available at JLC since it's so easy to just snap off the number of pins you need and solder them in place.

I am (per usual) unfashionably well past my deadlines, something my editors used to lament when I was writing professionally years ago. As Douglas Adams, the man who gave us "42!" once remarked,

"I love deadlines. I love the whooshing noise they make as they go by."

So I appreciate everyone's patience while I get this thing done. It's certainly nothing like I'd originally imagined when I embarked on this journey, and while Rome wasn't built in a day, I feel more like New York as one architect noted, "I love New York, it'll be great when they finish it".

So to answer your question (sorry for the long reply, but I figured an explanation was in order) the parts list isn't complete as yet. At least not one I want people to drop money on.

The capsule design hasn't changed so you can still make that with the JLI2555 (also sold as the TSI2555 in some places) with the 2N4416 JFET, the brass shielding and it's carrier assembly. That was always something I'd determined to keep (even though I've done PCBs to mount the JFET more easily, and allow for a wider variety of parts).

While I can't promise anything until I've actually TRIED it, many of the original parts can be reused with the new designs. I've scaled down the THAT1512 section with a through-hole and SMD version for instance and it's got a brand new power supply design that I'm currently putting the final touches onto.

Ironically, a whole lot of the pain I've suffered with this could have been avoided if the USB standards people had made a better cable design in the first place! I know WHY they did it the way they did now I've had time to analyse the issue. It is possible to make our own but pure USB 3 data cables are rather complex affairs. It might be possible to fix this on a USB A to USB C cable (which will only have four conductors plus screen).

I've got the adaptors on order to try this very fix and see how effective it is on real hardware. Fortunately they're not expensive and might provide a relatively "easy" way to make a USB-C to USB-C male-to-male cable several meters in length that won't put an intolerable amount of low-frequency noise on the power. What makes this one particularly troublesome is that 1KHz (the whine) is smack dab in the middle of where human hearing peaks! (Our ears are most sensitive to sounds in the speech frequencies from 300 to 3000Hz and a 1KHz square wave produces noise at 1KHz and has odd harmonics going 3KHz, 5KHz 7KHz and so on. The USB designers obviously didn't consider audio as being a thing when the interface was designed in the 1990s and we're stuck with it. (Keyboards and mice use slower polling rates incidentally.)

It's just possible that the adaptor cable (YouTuber "Great Scott" is on a similar quest right now) might reduce this noise to a degree that I won't have to jump through flaming hoops to tame it without breaking the specification. It's hypothetical at the moment but the idea shows great promise. But there's a catch (isn't there always?) soldering a USB type A is challenging if you're not well practised and the repair involves taking splicing an existing cable removing and wrapping a screen around the data wires, putting the power lead on the other side protected from USB data noise with the Faraday shield.

Such a cable could benefit a lot of USB mixed signal designs and make it easier for other makers to design high-gain audio gear that's powered purely from USB.

If you're wondering why no one addressed this before, the answer is many have and it all comes down to how small the signal is that you're starting out with. An electret mic such as we have here requires a gain of at least 100x; and Matt's original went to 1000x in fact.

CODECs (the single chip solutions) likely get around this because the ADC receives its power from an internal regulator that has enough bulk capacitance near to the chip to operate correctly. Higher-end ADCs, 24 and 32 bit devices need exceptionally quiet power supplies for similar reasons.

One other alternative I did try and this is available with our new module is MEMS digital microphones. They offer a relatively simple solution but the MEMS mics while good for speech don't come close to a large diaphragm condensor, or LDC, like the JLI2555. In conclusion we've gone from the ultimate USB-C mic to (I hope) the ultimate modular Makers microphone where you're in control over the various parts, mixing, matching and even upgrading as you go.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco Thanks for the reply. I appreciate all the background on your work, it sounds like a difficult process. I think I will build the capsule section as you suggest, and wait for the release of the v2 before completing the project, especially if you say there may be a Rasp-pi-like header socket version I could get the files for - it's definitely worth waiting to see if JLC are able to do that for me.

Thanks

I can rattle off a version of Matt's original for everyone reasonably quickly. The delays are rather ridiculous now and at least Matt's is predictable and a PCB version would be (a) much easier to solder due to the solder mask and (b) less error prone since you only have follow the silkscreen. I'm in the middle of a related module so I'll do that next and put the PCB on my GitHub. I'll mention it here but feel free to prod me if I don't remember! 🙂

Edit: Here's a PCB (you can use 2 or 4 layer, four layer is better). I've kept Matt's original circuit in its entirety but added some output protection (two Schottky diodes) so digitisers without input protection diodes should not end up in Silicon Heaven. I've added a couple of 100nF ceramic capacitors but they are not required.

There's a two and a four layer board here, dual layer can be made at home with the correct equipment because I've avoided Vias which are impossible to make at home. Quad layer boards only cost a few $s more and should offer better performance.

I should note that I haven't tested this PCB, although it passes the DFM. Many of the original parts can be recycled from Veroboard if you're careful.

I should also stress this is not V2 which remains under embargo until all of the modules are fully tested.

Whelp. See this is what happens when design a PCB without testing the effects. (Never let it be said that I'm not man enough to admit it when I drop the ball.)

This does work per Matt's original, but the Schottky's won't have the desired result as the output does need to cross GND (it's AC). So if anyone needs me I'll be stood at the back of the class with my Dunce's cap on.

I'll pop a corrected one up when the teacher tells me I can sit back down again. Sorry all.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

V1.5

Well, after receiving some timeless engineering wisdom from my dad, I think I will try building something based on Matt's original design and the single-channel Alice (although I need to find the schematic and BOM, as everybody and their dog seems to want to build exclusively dual-channel ones). However, what I want to do is to abandon powering the mic from USB and get a small power supply, like those used for old radio phones with stationary bases. That way, I will avoid (I hope) all negative effects that are caused by the USB-specific way of supplying power. I'm not bothered with having an additional wire on a table, I would rather spend a minute cable managing than years trying to battle problems in a search for a perfect solution of things that were never intended for each other, like how @marcdraco does)

The modular version I’m developing now uses that very solution (external power) in much the same way as some Arduinos do. We’re married to USB power (almost) because people don’t want the extra wall wart and I’m. The first to admit that it’s a massive pain. I did try to fix this by making up a special USB cable but even with that, there's still the issue of what's going on inside (any hubs) and the PC itself. The cable is only part of the issue.

It’s possible to solve this but it costs a lot than more than I was willing to force upon “makers”. Basically, it involves regenerating the 5V supply through a boost converter and then regulating it back down again. Most "low cost" boost converter modules produce as much noise if not more than USB, so this calls for very detailed design often with costly parts. In large numbers, 1000s of units, it's drop in the ocean, but when we're only making up two per prototype run, there are no bulk savings.

I know some makers are prepared to lay out hundreds but they are in the minority and most of Matt’s projects use small modules or parts that are accessible to a lot of people. I'm firmly in the keep it cheap, do it right camp. To some degree the more we can reclaim from other projects, busted mics and electronics we might find on eBay, etc. the better.

The challenge here is to:

- use as many parts from the original as possible. (Check, with some caveats.)

- improve on the performance of the original. (Check.)

- add digital mics. This isn’t an option I’m keen on as digital mics are MEMS and Omnidirectional. But they can be useful and don’t suffer with interference like many electrets do. (Check)

- keep costs low. This one is difficult to quantify as the new one is modular and ideally, someone will mass produce the main modules.

- Add in “wall wart” power. (Under development - not difficult but I want a solution that will last and dependent on one particular model!) Many of us have old switched-mode supplies lying around that can be pressed into service and it's things like this that are the beauty of DIY. A "perk" of DIY if you like.

Most of the improvement that have been added to V2 are under embargo, because:

- they might not make the final design. The digitiser - has already gone through seven discrete designs - one was my mistake, another couple were me getting bitten because a rather important factor was missing from CMI's datasheet. And yes you did read that right, rather than relying on the various commercial digitsers, I've developed something based on the CM108 that improves performance considerably over the usual "toy" 3D adaptors it's found in. CMI dropped its Xear tech for this chip following Windows 7 - which is a real shame since it added needed DSP functions. Its newer chips do have DSPs but that's where I hit the buffers at 100MPH; and talking to CMI is like shouting at clouds.

- they might not work as well as expected. It's astonishing with all the tools we have today but it's actually still acceptable (and expected) that designs will go through multiple iterations before final decisions can be made. See above.

- New functions only Matt and I know about are closely guarded because we've got a lot of time in this and loose lips might give another channel the head's up. 🤣

OPA Alice is deliciously simple to make but (and this is the catch) is that it has fairly specific power requirements. The design is intended for a P48 phantom standard although it's internally regulated down to 12V - which is split into a bipolar supply to power a dual op-amp. This is a JFET input design from TI/Burr-Brown that's widely claimed to be the best in its class. While a discrete JFET is generally better (for lower noise) there are other considerations that make the OPA2134 a great choice.

Sound Sleuth has the schematic and instructions and you can buy boards from PCBWay for the single and dual versions.

https://www.instructables.com/OPA-Based-Alice-Microphones-a-Cardioid-and-a-Figur/

What Alice can't do - and this is almost a given - is eliminate noise like that 1KHz whine although it should be less affected than a simple JFET due to the PSRR (power supply rejection). At 1KHz the PSRR is starting to fall way and since the 1KHz whine is producing odd harmonics up the entire audio band (and beyond) all bets are off. Alice mics are designed and intended for P48 which is (or should be!) a very smooth supply. Almost all the current mixers are mains powered - although a surprising number are still fairly modest designs. Focusrite are one of the exceptions but then you're getting the benefit of a multi-million $ company which probably (I don't know this for sure) is producing it's own ASICs.

Matt's original design won't drive Alice circuit because it's dual polarity and the P48 standard calls for a single supply with 10mA of drive - strictly it's closer to 14mA but you won't get any useful voltage at that load. P48 is pretty feeble actually, with many lower-cost East Asian P48s producing considerably less voltage even before they are loaded with a capsule and the associated impedance matching.

Apropos the Alice, I've done a version of "Varee" from last year that mounts to the capsule but has most of the Alice electronics on a really small board. I don't know if there will be much call for this so I'll probably just drop it on GitHub at some time. I'm leery of tempting fate by this point and I want to be 100% sure it works with the new pre-amp design. I does on paper but I've jumped from that confidence bridge before and hit the rocks below. 😶

The biggest claim for OPA Alice, compared to the simpler circuit with discrete transistors developed in the 1960s, is the incredible performance of a modern op amp vs. a simple JFET. Here's why this is misleading and ultimately wrong.

The catch that no one ever talks about. You'll be familiar with the phase about "the weakest link in a chain is where it breaks" or something along those lines. The weakest link in a well-made microphone, no matter who makes it, no matter how much it costs is the capsule. A modern op amp has THD (distortion) figures so low they are virtually immeasurable, TID (transient inter-modulation) is a different matter, and it's rarely specified, but that's not as massive a problem as sometimes claimed.

Even a great capsule (and we're talking capsules in mics that cost many $1000s) will exhibit distortions as high as 1% or more. Not to mention peculiar resonant peaks in some larger ones which may need to be corrected electronically downstream. Doug Ford (formerly of Rode Microphones) pointed this out and I'll reiterate this again, a mic for musical use is part of an art. A measurement mic (that's a mic with a "perfectly" flat frequency response) sounds ideal but if you listen to one they sound... well, flat.

Matt said (and was panned by some audiophiles, I see ya big dawg) for saying that mic design is as much an art form as it is a science. Sure, there's a lot of science in the electronics but the eventual output will often pass through a mixer and many stages of tonal "correction" controlled by the user to make a sound that sounds musically pleasing. A voice only microphone for podcasting can be made with a few very low-cost parts, a microphone that's versatile and musically pleasing covering everything from the spoken word (say an Audiobook) to an acoustic guitar is a much more detailed problem that is, as Matt said, as much an art as it is a science.

Consider for instance that pretty much every mic you're likely to have used has a round diaphragm. It's one of those things where familiarity has bred lack of innovation. In the early 2010s, a Swedish company filed a patent for a triangular diaphragm which sounds bonkers. But the argument (and it makes sense) is that a circular shape tends to resonate easily at numerous different frequencies - and resonances are distortions! The first Jurassic Park has a famous scene where a glass of water produces waves as the T-Rex approaches - and we can see there the waves moving across the water. The effect was done with a piano "string" being twanged and passing a vibration through the round glass.

If you're unfamiliar, you can do this by getting some water in a round glass and dropping a little in the middle - see how the waves flow out, hit the edge and move back in again. This is what happens to your microphone, albeit at a microscopic level - and that's the distortion and peaking. As of this writing these are still under patent and we can't just buy them off the peg. Here's a product with the marketing blurb. A circle can be thought of as an infinite number of triangles - so the triangle is the fundamental shape, and least likely to produce resonances. (Understanding that is easier intuitively than it is mathematically.)

https://isovoxbooth.com/en-gb/pages/isomic-voice-over-microphone

These points are something we've sought to fix for this new revision but the modularity means that it can be upgraded and other people will be free to add their own improvements or extra modules (digital or analogue). At the heart of it it all is the new digitiser design, unique to DIY Perks although it's not required to make up some variation of the V2.

I know people are often impressed by numbers. 192KHz sampling rate (or higher) for example when 48KHz is CD quality and 48 KHz is well above the Nyquist frequency for human hearing. So it's actually sufficient - particularly for home-studio use. What's more important is a very, very low noise floor which increases the usefulness of the microphone at low gains.

Nothing here is a criticism @cbrdmn, I'm happy to help if I can. I just wanted you to be aware this is a surprisingly thorny issue to get right while keeping the cost respectable. The easiest way to get an OPA Alice to work from USB (and first time) is to use a Focusrite - like the Solo which has everything in a single box with excellent performance.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

Hello, I'd like to start building this microphone soon, and I have a question. Has any of the information from the video changed? For example, the schematics, materials, and so on—if anything has been updated, could you please send the current list of everything needed?

Also, I want to thank you in advance. My budget is currently limited, so I really hope to get it right on the first try. Thanks again!

I have an updated board - based on the original video - but with some improvements I've developed for the V2 - due back from JLCPCB early next week. It was actually due here yesterday but wouldn't you know it, a Super Typhoon ("Ragasa") rudely stopped play. How dare Mother Nature get in the way!

The capsule design (TSI/JLI2555 and JFET hasn't changed so you can get cracking on that side of things. In fact the planned (and years late [ 😶 ] V2) has informed a few minor improvements that would have been difficult with Vero.

It's hard to say exactly when it will drop but the BOM is almost exactly the same as Matt's original with some optional parts. I've had to add a low-cost (i.e. should be under 1$) TL072 operational amplifier, a couple of "Schottky" diodes and some very low-cost ceramic capacitors. The moment I've built one up and tested it - it's not beyond the realms of possibility that I've messed something up as I have a lot of balls in the air right now - I'll publish it here and GitHub.

It's fully compatible with Matt's original so the rest of the BOM is unchanged, that includes the THAT1512, 2N4416 JFET, NMA0515SC, 2200uF capacitors and so on. Also the rotary switch and the resistor chain for that remain unchanged. The PCB will cost around $4 plus shipping and tax if you get it from JLC or PCBWAY for example. For that you'll usually get five complete boards with a sillkscreen so it's almost impossible to go wrong. All the JST sockets are two pin so you won't have to order odd ones.

The modifications are largely to reduce the chance (we can't eliminate it entirely) of blowing digitisers as some have poor (or non-existing) input protection.

You could make it on Veroboard but I'm not providing an overlay because Vero is a prototyping system meant for people who were already able to build stuff from scratch and the East Asian copies are fragile and poor copies. Modern standards really call for PCBs for almost anything and thanks to solder resist it's difficult to make a mistake and even if you do, it's a lot easier to mop up extra solder.

When I do finally finish the V2 - seems like the sun will go out first - you can use these parts in that too.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco great scott on youtube made a video on how to reduce noise in boost converters, will that help here?

Edit: Source: YouTube https://share.google/uXJnkzyOKrvbTW7f9

Unfortunately not, but thank you for thinking of me. The boost converter isn't the issue (although I did think it was for the longest time). The noise is cross-talk from the USB data-lines getting impressed onto the positive power.

Great Scott (who is a terrific guy) has got similar issues with USB. The "fix" (a partial one) that I did try, is to screen the USB +ve (and -ve ideally) from the data lines. It's a surprisingly difficult thing to do but even if that works out, there's still the issue of cross-talk inside the PC and any external hubs.

I just have to deal with the appx. 100mV (measured on my gear, but YMMV) USB signalling riding on those power lines. Now 1/10th of a volt doesn't sound much but if that gets into the sensitive bits (and it does) it gets amplified up the wazoo. This is why Matt used >4mF of capacitance - 400x the maximum "allowed" was necessary to reduce it. I've got a new test assembly up now but I goofed and missed an important change to compensate for the design change I'd made. D'uh. I've fixed that and drop it on the next order. CMI bit me on the bum again and I just heard about another function, described in the datasheet isn't actually available to plebs like me because it needs a driver.

The upside of that is every time this happens, I have to go back and find a better solution: which I have. It needs a small MCU - possibly a Pi Pico (we need something that's available, standardised and reliable). The STM32 is good but the various boards don't follow a standard size. Same with ESP32. I'm still cogent of the costs involved, so at Matt's suggestion I've compartmentalised things into smaller (mostly stand-alone) modules that can be expanded.

I've included 5v USB with large capacitors but this will switch to external power if that's available.

Take everything I say with a pinch of salt, I might be wrong and it's a very *expensive* way to learn!

@marcdraco Does the usb need data transmission? if not then i found this usb isolator, dont't know whether it will work. https://fiio.com/productinfo/392240.html, or maybe we can make battery powered mic?

Edit: just noticied that it needs data lines, my mistake.....

i also found these, https://www.amazon.com/Topping-Isolator-Compatible-PCM32bit-withstands/dp/B09MF9VTQG

https://www.aliexpress.com/item/1005001369085297.html

Edit: fixed the link.